Injection Molding Project

In a group of four for Northwestern's Computer Integrated Manufacturing course, we went through the full process of creating a customizable injection molded part, including two halves of the body, a top hat, and a mustache.

Skills Strengthened:

- CAD Modeling (Siemens NX)

- CNC Tool Path Programming (Siemens NX)

- CNC Milling

- Injection Molding

Modeling

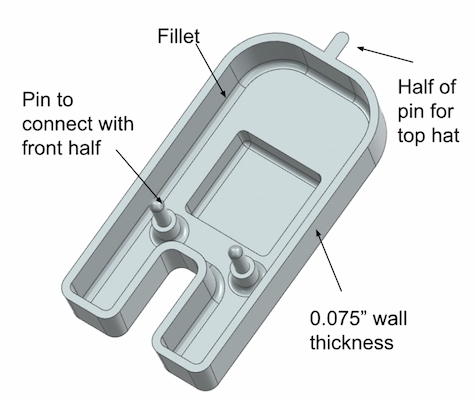

This project involved leading the end-to-end design and manufacturing process for a customized, two-part Among Us character and two attachable accessories (a hat and a mustache) using plastic injection molding. The primary goal was to gain expertise in creating parts optimized for mass production while ensuring reliable assembly through precise fitment. After selecting the concept of our product, we used NX CAD to create shells for the two halves of the part and the accessories. We focused on design choices important to successful injection molding like consistent wall thickness, avoiding sharp corners, and a 2 degree draft angle.

Mold Manufacturing

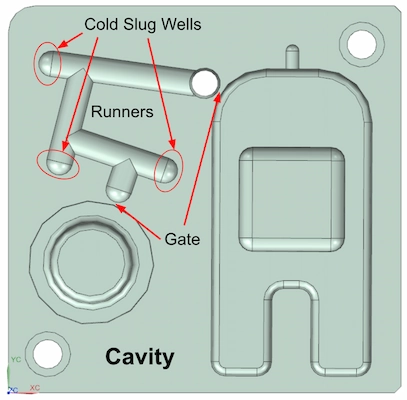

The project centered on CNC machining four aluminum mold halves (core and cavity). We used NX CAM to program various roughing and finishing operations to achieve a polished surface finish and desired interference fits for our pins. Besides just the parts models, we also had to machine in the sprue and runners for the plastics to travel through during the injection process. Calculations were done on the runner design to ensure both parts would fill simultaneously.

Quality Control and Process Tuning

The final stage focused on honing in injection parameters like injection time, pressure, and temperature to eliminate molding defects. We then examined quality control through a metrology study of 20 molded samples. By measuring critical features like the mustache pin diameter and hat height, we established a production average and calculated dimensional deviation. The measured parts showed consistent shrinkage, aligning with expected polypropelyne material behavior.